Strong, compact body

The main structure castings are made of high quality Meehanite cast iron, with stable structure and permanent quality assurance

Continuously shorten the acceleration/deceleration time of the spindle and change the tool time, increase the feed speed, reduce the auxiliary time, and improve the cutting efficiency

| Specifications | HMC63T?series | HMC-80T?series | ||||

| Project name | HMC63-T/1 | HMC63-T/2 | HMC80-T/1 | HMC80-T/2 | ||

| (single table) | (Exchange Workbench) | (single table) | (Exchange Workbench) | |||

| Bench | Working desk size | 630x700mm | 630x700mm | 800x800mm | 800x800mm | |

| Table indexing | 1°(0.001°) | 1°(0.001°) | 1°(0.001°) | 1°(0.001°) | ||

| Workbench maximum load | 1200kg | 1200kg | 1500kg | 1500kg | ||

| Maximum workpiece rotation diameter | φ1000mm | φ1000mm | φ1600mm | φ1600mm | ||

| Travel | Positive T layout | Workbench rotates left and right (X direction) | 1050mm | 1050mm | 1300mm | 1300mm |

| Spindle head up and down (Y direction) | 810mm | 810mm | 1000mm | 1000mm | ||

| Columns move back and forth (Z direction) | 900mm | 900mm | 1000mm | 1000mm | ||

| Spindle (Taiwan) [Synchronization Belt 1:1 Drive] | BT50 ring spray | Spindle bearing inner diameter | 100mm | 100mm | 100mm | 100mm |

| Maximum speed | 6000rpm | 6000rpm | 6000rpm | 6000rpm | ||

| Spindle centerline to table distance | 120~930mm | 0~810mm | 120~1120mm | 0~1000mm | ||

| Distance from the main bearing surface to the center of the table | 130~1030mm | 130~1030mm | 200~1200mm | 200~1200mm | ||

| Fast moving speed | X direction, Y direction, Z direction | 36m/min | 36m/min | 36m/min | 36m/min | |

| B axis | 10r/min | 10r/min | 10r/min | 10r/min | ||

| Magazine | Tool selection method | random | random | random | random | |

| Pull type | Type MAS 2 | Type MAS 2 | Type MAS 2 | Type MAS 2 | ||

| Number of tools | 40[60] | 40[60] | 40[60] | 40[60] | ||

| Maximum tool diameter (adjacent) | φ115mm | φ115mm | φ115mm | φ115mm | ||

| Maximum tool diameter (lead empty knife) | φ250mm | φ250mm | φ250mm | φ250mm | ||

| Maximum tool length | 450mm | 450mm | 450mm | 450mm | ||

| Maximum tool weight | 25kg | 25kg | 25kg | 25kg | ||

| Tool change time (tool to knife) varies with tool weight | 2.5s | 2.5s | 2.5s | 2.5s | ||

| Tool change time (cut to cut) varies with tool weight | 6s | 6s | 6s | 6s | ||

| APC | Pallet exchange | 2-sided rotation | 2-sided rotation | |||

| Pallet exchange time | 15s | 15s | ||||

| Positioning accuracy (GB) | X direction, Y direction, Z direction | 0.01mm(full course) | 0.01mm(full course) | 0.012mm(full course) | 0.012mm(full course) | |

| Repeatability | X direction, Y direction, Z direction | 0.006mm(full course) | 0.006mm(full course) | 0.008mm(full course) | 0.008mm(full course) | |

| CNC system | ?FANUC system,SIEMENS system,Mitsubishi?system | |||||

| Standard configuration | Optional configuration |

| Spindle speed 6000RPM | Spindle speed 8000RPM |

| Spindle airtight system | Three-axis grating |

| Spindle roller track | Fourth axis scale |

| Worktable 1° graduation | Spindle outside blowing system |

| Cutting fluid ring spray | Spindle Center Outlet System |

| Scraper drainage system | FANUC 31IMD |

| Chip collection trolley | ZF gearbox |

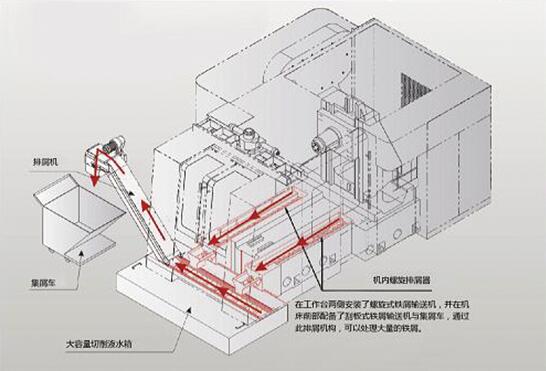

| nternal screw chip removal system | Spindle oil cooler |

| Internal oil and water separation system | Triaxial hollow cooling system |

| Roof punch system | |

| Water separator | |

| M30 automatic disconnection system | |

| working lamp | |

| Warning Light | |

| Electric box heat exchanger | |

| ?FANUC OIMD |